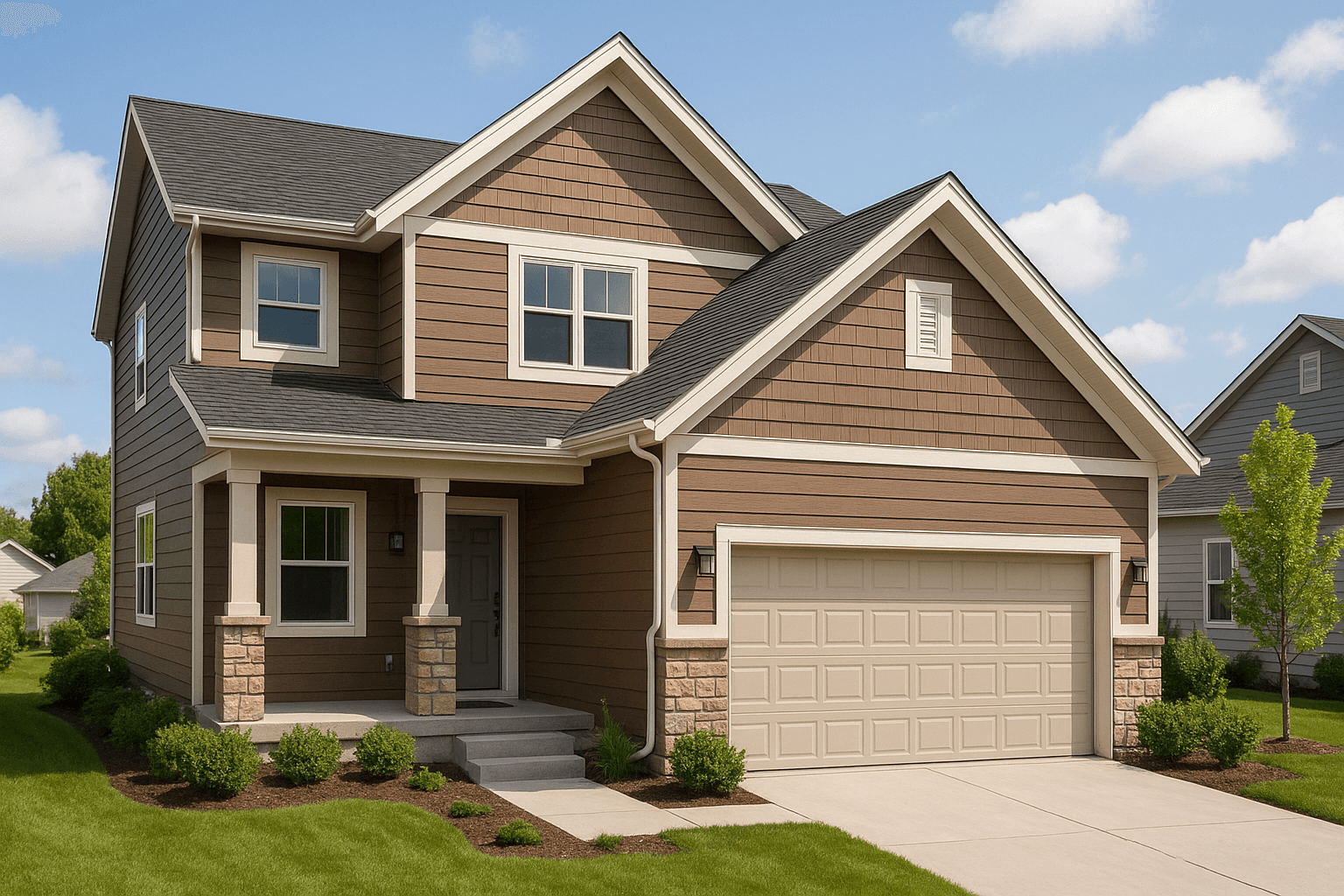

Every home tells a story, and the siding is the cover you see from the street. For Utah homeowners and business owners, that cover has changed a lot—especially with the rise of Engineered Wood Siding. It’s wood, and somehow not. It looks warm and natural, yet it’s built with science. The evolution didn’t happen overnight; it came from hard-won lessons, better chemistry, and the kind of field testing only snow, sun, and the Wasatch winds can deliver. If you live or work around Salt Lake City, this history matters—because climate and craft go hand in hand here.

From Solid Timber to Sheet Goods: The First Big Shift

Before anyone talked about “engineered,” siding meant boards: cedar, pine, maybe redwood on the high end. In Utah, that classic look still turns heads. But natural wood needs steady care—paint cycles, pest vigilance, and close attention at south-facing walls that cook under high-altitude sun. Those wide temperature swings we get here? They tug at fasteners and stress coatings. Beauty, yes; easy, not always.

Mid-century brought sheet goods—plywood and hardboard (you might remember Masonite). They promised a smooth, modern look with fewer seams. On paper, it seemed perfect. In practice, some of that early hardboard swelled when it got wet, especially at cut ends and trim lines. Seams bubbled. Paint failed. Homeowners weren’t thrilled, and neither were installers who had to return with caulk guns and apologies. Those hiccups taught the industry a blunt lesson: wood fibers need better protection from moisture, fungi, and UV. That lesson fueled the next big step.

The Birth of Engineered Wood Siding

Here’s the thing: engineered wood siding isn’t just compressed sawdust. It’s strands or fibers arranged for strength, bonded with durable resins, and treated with protective additives. That structure creates consistent, predictable panels and lap boards that stand up to weather in ways solid lumber can’t always match.

The 1990s saw bold attempts and a few well-known missteps. Some early products underperformed in wet conditions, sparking lawsuits and a hard reset. Manufacturers went back to the lab. Moisture barriers improved. Resins changed. Quality control ramped up. The market didn’t give second chances lightly—but it did give them, and that’s when engineered wood started to hit its stride.

The Second Generation: Science Meets Sawdust

When manufacturers began using zinc-borate treatments throughout the board (not just on the surface), things clicked. Brands like LP SmartSide pushed the category forward with:

Protective chemistry that resists rot and termite damage.

Waxes and resins that help repel water and reduce swelling.

Edge sealing and factory primers that guard the most vulnerable spots.

Let me explain how that plays out on a wall. You get the look of wood grain pressed right into the board—crisp, consistent, and surprisingly convincing from curb distance. The boards handle impact well, which is a relief during Wasatch Front hail squalls or when a ladder bumps a wall on a windy day. Crews also work faster since the material is light and easy to cut, which matters during shorter winter daylight hours or tight business schedules.

Is it perfect? Nothing is. But compared to early sheet goods and even some natural species in our dry-cold climate, modern engineered wood has a pretty steady track record.

Coatings, Colors, and Texture: Aesthetic Evolution

There’s the science, and then there’s the finish. Factory priming came first. Now many lines offer factory finishing with rich, UV-stable color systems. If you’ve driven through neighborhoods in Daybreak or Sugar House and admired crisp lap siding with deep shadow lines, there’s a good chance you’ve seen engineered boards with factory paint.

High-altitude sun in Salt Lake City is no joke. Pre-finished options like LP’s ExpertFinish or partner systems such as Diamond Kote use tough color layers designed for that harsh UV. You get classic cedar texture, smooth minimalist panels, or rustic shakes. It’s funny—engineered siding often looks more like traditional wood than older wood products ever did. That consistency helps designers mix styles: mountain modern, craftsman, contemporary farmhouse, or clean commercial storefronts. Yes, even retail and restaurant facades benefit from that warm texture without the constant scraping and repainting.

Performance in Utah’s Climate: Why It Caught On Here

Our climate swings. Winter snow. Spring melt. Intense summer sun. Occasional downpours. Wildfire ash. Then the inversion sits and traps moisture right when you don’t want it. Siding here needs to breathe but not soak, flex but not fail. This is where modern engineered wood siding holds up well:

Freeze-thaw resistance thanks to consistent density and protected edges.

UV tolerance with factory finishes that keep color truer, longer.

Impact resistance that shrugs off stray soccer balls, gravel spray, and roof debris sliding down in a thaw.

And for builders and facilities managers: it’s easier on crews in cold months. It cuts cleanly, weighs less than many fiber cement boards, and keeps projects moving when time is tight. You know what? That predictability alone can save a schedule.

Engineered Wood vs Fiber Cement vs Natural Wood: An Honest Comparison

Each material has a lane. Picking the right one is about goals: look, budget, code, and maintenance appetite.

| Property | Engineered Wood | Fiber Cement |

|---|---|---|

| Weight | Light; faster handling | Heavier; more muscle and cutting gear |

| Impact Resistance | Good; resilient against dings | Fair to good; can chip if struck |

| Moisture Behavior | Stable with proper detailing | Very stable; not organic |

| Fire Response | Improved, but it’s still wood-based | Non-combustible; strong in WUI zones |

| Installation Speed | Fast; common carpentry tools | Slower; specialized blades, dust control |

| Maintenance | Repaint cycles; long substrate warranties | Repaint cycles; very durable substrate |

| Look | Warm, convincing wood texture | Crisp lines; texture options improving |

| Cost of Ownership | Competitive; labor savings help | Competitive; long-term durability |

And what about natural wood? It’s beautiful. For many historic homes, true cedar is still the right move. But it asks for regular attention—especially on sun-blasted or windward sides. In short: if you want the look with less fuss, engineered makes sense; if you want non-combustible cladding for a strict fire zone, fiber cement wins; if you want authentic grain and don’t mind hands-on maintenance, natural wood remains a classic. We install all three and match the material to your site, style, and schedule.

Modern Install Practices: Small Details, Big Payoff

Materials matter, but detailing is where projects succeed. A few small steps carry a lot of weight in our region.

- Weather-resistive barrier done right. Use a quality WRB (think Tyvek or a robust alternative), and integrate it with windows, doors, and penetrations. Tapes matter. Sequencing matters.

- Rainscreen spacing. A simple batten or drainage mat behind siding lets walls dry after storms or snowmelt. It’s a small cost with a big upside for longevity.

- Flashing at every joint. Kick-out flashing at roof-to-wall, Z-flashing over horizontal breaks, and pan flashing at sills. Water wants in; give it a path out.

- Cut-end treatment. Seal every cut with the manufacturer’s approved primer/paint. Factory edges are tough; field cuts need love too.

- Proper clearances. Keep siding off decks, roofs, and sidewalks. Snow piles and splashback are real in Utah winters.

- Nailing and spacing. Follow the listed nailing schedule and leave the right gaps for expansion where required. It’s not fussy—it’s smart.

These steps aren’t glamorous, but they’re the difference between a siding job that merely looks good on day one and one that still looks good in year fifteen.

Sustainability Story: From Waste to Worth

Engineered wood takes fast-growing trees and uses fibers efficiently. That means fewer big old trees cut and more consistent yield from working forests. Many products are SFI or PEFC certified, and factory finishing reduces jobsite VOCs compared to field-applied coatings. Want a lower embodied carbon profile than concrete-heavy claddings? Wood-based products usually score well there.

There’s nuance here. You still need responsible forestry and careful transport. But turning fibers that might have been scrap into durable cladding is a good story—especially when the panels last decades and can be maintained rather than replaced.

Where It Fits: Homes, ADUs, and Commercial Facades

We see engineered wood siding thrive across project types in the Salt Lake Valley and the benches:

Single-family homes that want the warmth of wood without constant staining.

ADUs and additions where speed matters and budgets are firm.

Townhomes and multifamily where crews need repeatable installs with consistent QC.

Retail fronts that need character and easy touch-ups after sign changes or seasonal decor.

And yes, code always matters. For stricter fire zones or wildland-urban interfaces, we often recommend pairing engineered wood accents with non-combustible cladding on hot sides, soffits, or near property lines. There’s no one-size-fits-all wall, and that’s okay—we design the assembly to your exact site and use.

What’s Next: Smarter Siding on the Horizon

Manufacturers keep nudging the category forward. Expect:

Even tougher finishes with improved UV chemistry and longer color warranties.

Hidden-fastener profiles that speed installation and sharpen lines.

Integrated drainage layers that simplify rainscreen details.

WUI-minded trims and accessory metals that stand up to embers where codes demand it.

Honestly, the biggest change might be invisible: better factory QC. Sensors and smarter press controls reduce variability from board to board, and that consistency shows on the wall.

Local Notes from the Field: Utah Siding & Exteriors

We’ve watched this category grow from the early days, and we’ve installed thousands of linear feet across Salt Lake City, Park City, Draper, and beyond. A few real-world takeaways:

Cut ends are everything. Seal them in winter and summer, no excuses. That one small step prevents swelling at butt joints.

Flash the belly band. Horizontal trims catch water. A simple Z-flash keeps it out of the sheathing.

Mind the sun. South and west walls need the best coatings. If your site bakes, consider a factory finish with strong UV data.

We’ve replaced aging hardboard on a Sugar House bungalow with engineered wood siding that kept the historic profile. We’ve installed smooth modern panels on a commercial facade in South Salt Lake for a clean, durable look. We’ve set shake accents on a Park City chalet that had to handle freeze-thaw and snow sliding off a steep roof. Different styles, same principles. Good materials. Better detailing. And steady follow-through.

Ready to Talk Siding? Let’s Keep Your Project Moving

If you’re weighing engineered wood siding for a remodel, new build, or a multi-unit property, we’re here to help you pick the right path. We’ll walk you through material choices, rainscreen options, trim details, and color systems that hold up under our Utah sun and snow. We’ll also give you a clear schedule and clean, predictable pricing—because surprises belong in powder days, not on your jobsite.

Call Utah Siding & Exteriors today at 801-509-9241, or tap below to Request a Free Quote. Let’s make your exterior look great now—and stay that way for years.