Metal siding gets a lot of rumors thrown at it. Some are half-true. Some are way off. If you’re a homeowner in Sugar House or a business owner along State Street, you’ve probably heard the same lines: it’s noisy, it dents, it looks like a barn. Here’s the thing—today’s metal siding isn’t the stuff your grandpa installed on a shed in the 70s. It’s engineered, tested, and styled for real homes and real businesses across the Wasatch Front. And in a climate like Salt Lake City’s—snow, sun, wind, repeat—that matters.

Myth 1: “Metal siding is loud.”

You know what? Rain on an old metal roof can be pretty loud—on an open barn, with no insulation. That image sticks. But walls aren’t roofs, and modern wall systems are built to be quiet. When metal siding is installed over sheathing, housewrap, and insulation, the assembly absorbs sound. The panel is fastened tight to a stable base, not flexing like a drum. Storm rolling off the Oquirrhs? You’ll hear the wind before you hear your siding.

For homes, that means peace during a summer downpour. For offices or retail spaces, it means customers won’t notice a thing. With a typical wall stack—OSB or plywood, air and water barrier, optional continuous insulation, then panels—field tests show a normal indoor noise level. Not dead quiet. Just, you know, normal. Like it should be.

Myth 2: “It rusts in Utah winters.”

Salt Lake City winters can be tough: freeze-thaw, slush, de-icing salt on roads. But modern Steel Siding uses corrosion-resistant alloys and coatings that are designed for this exact reality. Most steel panels are galvanized or Galvalume coated, then finished with durable paint systems—think PVDF resins like Kynar 500 or Hylar. These coatings resist UV fade and protect against corrosion, even with our high-altitude sun.

We still follow smart details. Keep ground clearance. Use correct trim at the base. Don’t trap moisture behind the panel. With proper install and reasonable care, rust just doesn’t show up the way people fear. Many manufacturers back this with long finish warranties—often 30 years or more. And because this is a dry climate, you’ve already got an edge.

Quick tip: if your property sits near salted roads where plows throw spray, a simple spring rinse helps. Five minutes, garden hose, easy maintenance.

Myth 3: “Hail will dent it.”

Hail happens along the Wasatch Front, though our biggest hail is usually hit-or-miss. Still, it’s smart to plan. Here’s the straightforward truth: steel is tough; aluminum is softer. Thicker gauges are tougher than thinner gauges. Panels with supported profiles resist impact better. And many steel siding lines carry UL 2218 Class 4 impact ratings—the same rating used for high-resistance roofing.

Can a big hailstone dent a thin aluminum panel? Sure. Can a Class 4 steel panel shrug off typical storms? Yes, often. And even when there’s a mark, it’s usually cosmetic, not structural. We match gauge and profile to your property’s risk. For businesses with high-traffic facades or western exposure, 26-gauge steel with a sturdy profile is a strong choice.

| Panel Type | Typical Gauge | Impact Outlook |

|---|---|---|

| Steel lap or board-and-batten | 26–28 ga | Strong against common hail; some lines Class 4 |

| Steel standing seam (wall use) | 24–26 ga | Very strong; profile adds rigidity |

| Aluminum planks | .024–.032 in | Lightweight; more ding-prone in larger hail |

Brands like EDCO and Quality Edge TruCedar offer steel siding designed to resist hail and keep its shape. We’ve seen these products hold up very well across Salt Lake County.

Myth 4: “Metal makes homes hotter in summer and colder in winter.”

Metal moves heat quickly; that part is true. But wall assemblies are layered. The siding is one layer. The insulation behind it does the heavy lifting. Many residential metal siding systems include foam backers or pair well with exterior continuous insulation to cut thermal bridging. Even without added foam, you’ve got your cavity insulation, air barrier, and sometimes a ventilated rainscreen gap that helps the wall dry. That combination controls comfort.

Also, modern finishes reflect heat. “Cool” paint pigments can reduce surface temperature compared with older coatings. Pair that with tight flashing and good air sealing, and comfort improves. We’ve retrofitted mid-century homes in Millcreek and seen summer indoor temps stabilize—without changing the HVAC.

Bottom line: when installed as part of a proper wall system, metal siding doesn’t make your home run hot or cold. It looks sharp and performs steady, season after season.

Myth 5: “Metal attracts lightning.”

This one hangs around, but lightning isn’t drawn to metal siding. The National Fire Protection Association notes that lightning seeks the highest path and the shortest route to ground, not metal itself. If anything, noncombustible steel siding lowers fire risk compared to wood products. In wildfire-prone zones along the foothills, that’s a real advantage. Sparks land; metal doesn’t ignite. That peace of mind is hard to beat.

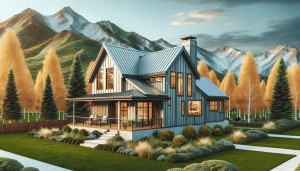

Myth 6: “It only works on barns or ultra-modern boxes.”

We hear this a lot. But walk around 9th and 9th or newer business parks in South Salt Lake and you’ll spot metal on craft homes, townhomes, coffee shops, and clinics. Profiles have come a long way. You can get clean standing seam, crisp shiplap looks, classic board-and-batten, or subtle horizontal lap with shadow lines that mimic wood. Finishes range from matte black to warm woodgrains like Walnut or Cedar—seriously convincing from the sidewalk.

Manufacturers like EDCO offer embossed wood-look steel that carries the warmth without the upkeep. For commercial projects, a mix of panel widths and colors can match a brand palette and punch up curb appeal. Done well, it feels timeless, not trendy.

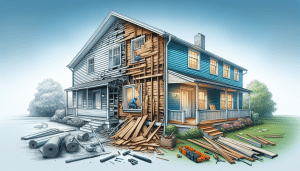

Myth 7: “Metal siding costs too much.”

Upfront, quality metal often costs more than budget vinyl and can be similar to fiber cement. But zoom out. The long-term numbers are where it shines. Coatings last. Panels resist pests, rot, and flame. Repainting cycles stretch far apart—often decades instead of years. Fewer repairs and fewer paint jobs add up.

- Fewer repaints. PVDF finishes don’t chalk and fade like cheaper paints. That means stable color and lower maintenance.

- Resale signal. Buyers like durable, low-fuss exteriors—especially in weather-prone areas.

- Insurance perks. Some carriers give credits for Class A fire resistance or Class 4 impact. Not always, but it’s worth asking.

So yes, the sticker might feel higher on day one. But the life-cycle cost? Often lower than it seems—especially if you plan to stay put.

Myth 8: “It’s maintenance-free.”

Almost. But let’s be honest: nothing outdoors is truly maintenance-free in a four-season climate. Metal siding is very low maintenance, though. A light rinse and soft brush clean once or twice a year is usually plenty. Touch up any deep scratches with manufacturer paint pens. Keep landscaping off the panels so moisture and soil don’t sit against the finish. And don’t point a pressure washer straight into panel laps or seams. That’s it.

Call it what it is: low maintenance that looks good with minimal effort.

Myth 9: “Any contractor can install it.”

Metal is forgiving in some ways and fussy in others. Thermal movement matters. Fastener type and spacing matter. Flashing and end details matter a lot. Getting the rainscreen gap right, hitting stud lines cleanly, using color-matched coil for custom trims—these are the small things that make the siding last and look sharp.

As a local siding contractor in Salt Lake City, we’ve worked through canyon winds, lake-effect snow, and the high UV at altitude. We plan for expansion joints, specify the right PVDF-coated systems, and coordinate with your roofer and window installer so the whole envelope works together. Permits, HOA coordination, and inspections—we handle those too. The result is a clean install that stays tight and beautiful.

The quick cheat sheet

| Myth | Reality | Why it matters |

|---|---|---|

| It’s noisy | Modern assemblies are quiet | Comfort in storms and wind |

| It rusts fast | Coated steel resists corrosion | Longer life and better looks |

| Hail trashes it | Steel panels resist impact; Class 4 exists | Fewer repairs after storms |

| It overheats | Insulation and cool finishes help | Comfort and energy savings |

| Attracts lightning | Not how lightning works | Safety and fire resistance |

| Looks like a barn | Many profiles and wood-look finishes | Fits homes and businesses |

What matters in Salt Lake City specifically

Our area is tough on exteriors. Big temperature swings, mountain winds, late spring snows, and strong sun. Metal siding in Salt Lake City handles that mix well. Steel doesn’t warp with heat. Coatings fend off UV. And noncombustible cladding adds a buffer in ember-prone seasons near the foothills. If your property sits along a busy street, you also get a surface that doesn’t chip easily from small road debris. It cleans up fast, which keeps storefronts inviting.

HOAs? Many now approve wood-look steel with matte finishes because it keeps a neighborhood aesthetic without the repaint cycle. We help with samples and submittals so you can show exact color and profile before a vote.

How to choose the right metal siding

Let me explain how we help folks narrow it down. We look at a few simple levers: material, coating, profile, and wall build.

- Material. Steel for strength and hail resistance; aluminum for coastal or specialty needs.

- Coating. PVDF (Kynar 500) for color stability and UV; SMP is budget-friendly but chalks sooner.

- Profile. Horizontal lap for classic look; board-and-batten for farmhouse modern; standing seam for sleek, commercial lines; corrugated accents for texture.

- Insulation. Foam backers or exterior rigid insulation improve comfort and help with energy codes.

- Color. Matte black and charcoal are popular here. So are woodgrains and warm grays that pair well with stone.

We’ll talk through wind exposure—bluff near the Avenues or tucked-in lot in Murray—and pick fasteners and details that match your site. Small choices, big payoff.

Brands and finishes we trust

We install lines from manufacturers known for field-tested coatings and strong warranties, including EDCO steel siding and Quality Edge TruCedar. Their finishes resist Utah UV and hold color well. Where a project calls for specialty looks, we source from suppliers like Bridger Steel for standing seam or custom profiles. That doesn’t mean every job needs premium everything—just that you get the right product for your building and your budget.

A quick word on sustainability

If you care about waste, steel siding is a solid pick. Steel is widely recycled, and most panels include recycled content. The long service life means fewer tear-offs over time. Fewer paint cycles mean fewer solvents in the mix. It’s practical, not preachy, and it fits the way a lot of Salt Lakers think about stewardship—smart, durable, and not fussy.

Why Utah Siding & Exteriors

We live and build here. That means we’ve seen what works on the west bench and what gets beat up near the canyons. We coordinate with local inspectors, keep an eye on HOA requirements, and stand behind our work. Our crews understand metal’s small details—clips, trims, movement joints—so you don’t get rattles, leaks, or oil-canning that distracts from the clean look.

From bungalows to breweries, clinics to condos, we’ve helped property owners move past the myths and get the performance they want. And yes, we bring color samples, mockups, and honest advice. No pressure.

Ready to bust the myths for your place?

If you’re weighing your siding options and want straight talk for your home or business in Salt Lake City, we’re here to help. Call Utah Siding & Exteriors at 801-509-9241 and tell us what you’re planning. Or click to Request a Free Quote and we’ll follow up fast. We’ll bring samples, measure, and give you clear numbers—no guesswork, no fluff. Let’s build something that looks great and lasts.