Salt Lake City keeps you guessing, doesn’t it? Bluebird mornings, surprise afternoon showers, long freezes, and heavy sprinkler use through summer—moisture shows up in sneaky ways. If your siding can’t handle water, it’ll show: swelling trim, peeling paint, soft spots along the foundation. Here’s the thing—wood and water usually don’t get along. But Engineered Wood Siding isn’t ordinary wood. Built with smart resins, waxes, and proven treatments, it stands up to wet seasons, snowmelt, and day-to-day splashback that would wear out other claddings. This guide explains why engineered Wood Siding is a strong solution for high-moisture climates and how Utah Siding & Exteriors installs it right for homes and businesses across Salt Lake City, UT.

Why moisture is so tough on Utah exteriors

Salt Lake City might be semi‑arid, but moisture is everywhere it counts. Snow stacks up, melts slowly, and refreezes in shady spots. North-facing walls stay damp. Sprinklers soak lower courses every summer night. Then come spring storms rolling off the Wasatch, plus wind-driven rain along the benches. That’s a lot of wet stress on any building skin.

Water doesn’t have to pour in to cause trouble. It creeps. It wicks into end grains. It hides behind trim. Add freeze–thaw cycles and UV at elevation, and weak siding will swell, crack, and shed paint. If you’ve ever noticed those wavy lap boards or mushy corners near concrete, you’ve seen it.

So the goal isn’t to block every raindrop—that’s impossible. The goal is smart moisture management: shed, drain, dry. And that’s where modern engineered wood siding shines.

What engineered wood siding actually is

Let me explain. With natural cedar, you get beautiful grain—but also knots, variable density, and parts that really dislike standing water. Engineered wood siding takes wood fibers or strands and bonds them with weather-resistant resins and waxes under high heat and pressure. Then the boards get factory edge-sealing and primer. Many brands add zinc borate throughout the panel to resist rot and insects.

It sounds technical—and it is—but the takeaway is simple: uniform strength, reliable moisture control, and authentic wood texture without the drama. Common brands we install in Utah include LP SmartSide (including ExpertFinish colors) and KWP. Both deliver that crisp, wood-like profile that vinyl can’t mimic.

Wood plus water? Usually a no. Engineered wood plus water? Surprisingly steady, because the vulnerable parts are protected long before a board reaches your wall.

Moisture-fighting features you’ll actually notice

Not all siding handles water the same way. These built-in features make a real difference in wetter conditions and along snow-packed walls:

- Resin-and-wax core: Hydrophobic binders help limit water absorption and swelling, especially at edges.

- Zinc borate treatment: This adds decay and insect resistance throughout the board, not just on the surface.

- Factory edge-seal and primer: End cuts are the most vulnerable points; pre-sealed edges reduce wicking and paint failure.

- Impact strength: Products like LP SmartSide stand up to hail and kicked-up debris better than many fiber cement and vinyl options.

- Lightweight, easy handling: Faster installs reduce jobsite exposure to surprise storms—less time open, fewer headaches.

You know what? Even the best board fails without a good wall system. That’s why we pair siding with a drainable housewrap and, when the design calls for it, a slim rainscreen gap so walls can dry quickly after storms or snowmelt.

How it compares to fiber cement, vinyl, and cedar

Every cladding has tradeoffs. Quick comparison below for moisture-heavy conditions in Salt Lake City:

| Siding Type | Moisture & Durability | Maintenance & Notes |

|---|---|---|

| Engineered Wood (LP SmartSide, KWP) | Resin/wax core resists swelling; strong impact resistance; stable edges with proper sealing. | Repaint cycles can be long with factory finishes; easy to repair; lightweight for faster installs. |

| Fiber Cement | Very moisture tolerant; heavy; more brittle on impact; cutting produces silica dust—requires controls. | Paint holds well; more labor to cut and lift; great fire performance. |

| Vinyl | Won’t absorb water; can rattle in canyon winds; susceptible to hail and UV distortion. | Low maintenance; limited “true wood” look; repairs can be conspicuous. |

And cedar? Gorgeous, yes. But it needs more care in our freeze–thaw seasons, careful clearances from grade, and vigilant finishes. Many homeowners who love a classic look choose engineered wood siding instead because it keeps that wood grain vibe without constant upkeep.

Built for the Wasatch Front: performance in SLC’s climate

Between high UV, quick temperature swings, and snowpack that lingers on shaded walls, Salt Lake City can be hard on standard claddings. Engineered wood handles that rhythm well when it’s installed as a system:

- Freeze–thaw resilience: Sealed edges and a drainable assembly help prevent water from sitting where it shouldn’t.

- Hail and wind: The dense substrate of products like LP SmartSide helps resist dents and cracks during summer storms.

- UV at elevation: Factory-applied finishes (e.g., ExpertFinish) are formulated for color hold.

- Wildfire concerns: Many engineered wood products carry a Class C rating. In high-risk foothill zones, we can design assemblies that improve ember resistance or discuss alternatives like fiber cement.

We also pay attention to microclimates: alley-facing walls that never see sun, splash zones along walkways, shady north gables, or commercial façades hit by snowplows. Little details—like extra drip flashing or a rainscreen in those spots—pay off big over time.

Looks matter: styles for homes and businesses

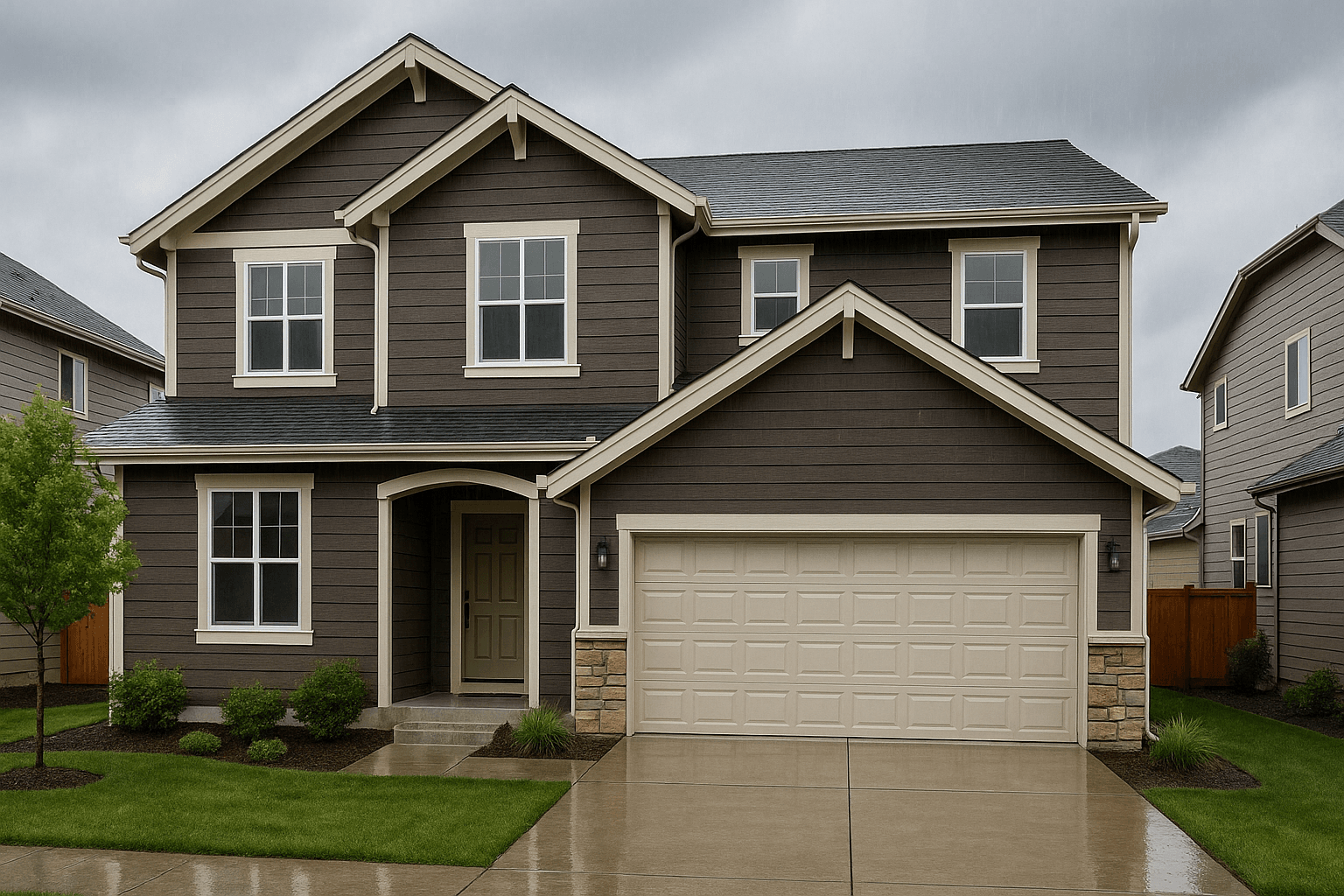

Whether you’re refreshing a Sugar House bungalow or re-skinning a warehouse office near Granary, engineered wood siding can match the look:

- Lap siding: Clean lines for classic cottages or modern builds.

- Board-and-batten: Tall, vertical rhythm; perfect for mountain-modern homes and agrarian-inspired storefronts.

- Shakes and panels: Texture for gables or accent walls without the maintenance of real shakes.

Color? You’ll find wide palettes in factory finishes that arrive ready to hang—no waiting on weather for paint to cure. Want custom? We prime and paint with exterior, high-solid coatings that shrug off wet seasons.

For businesses, uniform profiles and long color cycles keep façades camera-ready for years—useful for brand consistency across multiple properties.

The install: small details, big difference

Even the strongest siding can fail if shortcuts creep in. Our crews follow manufacturer guidance and regional know-how. A quick snapshot of what we do on Salt Lake City jobs:

- Weather-resistive barrier: High-quality housewrap with taped seams, integrated flashings, and pan details at windows and doors.

- Rainscreen when needed: A slim drainage gap (often 3/8 in.) that lets walls dry faster—huge near shaded elevations and sprinkler zones.

- Right clearances: Off concrete, decks, and rooflines to prevent wicking; kick-out flashings at roof-wall intersections.

- Proper fasteners: Corrosion-resistant nails, correct embedment, and tight but not crushed laps.

- End sealing and joint flashing: We seal cuts as we go and flash butt joints to keep edges strong.

- Sealants where they count: High-performance, paintable sealants at key transitions (not everywhere—that can trap moisture).

We know it sounds fussy. But these steps are what separate long-lasting walls from “looked great for two years.” When you hire Utah Siding & Exteriors, you’re getting a partner who sweats the small stuff so you don’t have to.

Care and upkeep: simple, predictable, quick

Good news: maintaining engineered wood siding is straightforward.

- Wash gently: Garden hose and mild soap remove dust and pollen; skip aggressive pressure washing up close.

- Touch-up edges: If you nick a board during yard work, touch it up—same as you would with any painted surface.

- Repaint cycles: Factory finishes can go many years before repainting; field-painted systems vary by color and exposure, often 7–10 years.

- Seasonal check: Spring and fall, peek at caulk lines and flashings. Five minutes now beats a repair later.

Honestly, many homeowners tell us they forget about their siding for long stretches—and that’s kind of the point.

Cost, warranties, and long-term value

Upfront, engineered wood siding typically lands near fiber cement and above mid-tier vinyl. But it installs faster than fiber cement and handles hail better than many vinyl products, which can mean fewer future headaches. Consider the full picture: install time, repaint cycles, repair ease, and curb appeal.

Most major brands carry strong limited warranties—often 30 to 50 years on substrate with finish warranties on factory colors. We walk you through what’s covered so there are no surprises. We also register warranties and hand you a maintenance guide so the coverage stays intact.

Business and multifamily: schedule-friendly, durable, good-looking

For property managers, HOAs, and business owners, moisture trouble shows up in the same places: stair towers, trash enclosures, snow-drift corners, and busy entries. Engineered wood siding shines here because it’s tough, looks premium, and installs efficiently—less downtime for tenants and customers. Need after-hours work along a storefront? We coordinate to keep you open. Need value engineering that doesn’t look cheap? We’ll map a hybrid system with accent panels where they pop and durable laps where they take abuse.

When engineered wood isn’t the right call

It’s great—but not for every situation. If your project sits in a very high fire-severity zone, we’ll discuss assemblies and alternatives like fiber cement or metal. Super high-heat process buildings or heavy chemical exposure? Different claddings may fare better. You’ll always get straight talk from us, because fit matters more than forcing a single product everywhere.

Local know-how: Why choose Utah Siding & Exteriors

We’re a local siding company Salt Lake City homeowners and businesses call when moisture problems won’t quit. Our team has handled everything from Avenues cottages to flex spaces in South Salt Lake. We plan for freeze–thaw, snow sliding off metal roofs, and that stubborn sprinkler overspray near sidewalks. We use manufacturer-approved methods, document the install, and leave you with a clean site—plus a wall system built to breathe and shed water.

Looking for a second opinion on a repair vs. full Siding Replacement? We’ll assess honestly and show you photos of what we see behind the scenes. If your project calls for other materials—fiber cement, metal, or mixed façades—we handle that too.

Ready to weatherproof your exterior?

If you want siding that looks like wood but shrugs off wet seasons, engineered wood siding is a smart, good-looking choice for high-moisture climates—even in the tricky microclimates around Salt Lake City, UT. Tell us what you’re planning, and we’ll bring samples, talk colors, and design a wall system that’s built to dry fast and stay gorgeous.

Call 801-509-9241 to talk with a real person today, or click Request a Free Quote and we’ll follow up quickly.

Utah Siding & Exteriors—your friendly, detail-obsessed Salt Lake City siding contractors who care about what happens after the first storm, the first thaw, and the first hail season.