If you manage a storefront, a warehouse, or a mixed‑use building along the Wasatch Front, you probably think about two things a lot: how your place looks and how much it costs to keep it that way. Here’s the thing—Steel Siding for commercial buildings checks both boxes. It’s tough, clean, and built for our Salt Lake City weather. It can look sleek and modern or classic and timeless. And it’s not just a pretty face; it’s a smart, long-term play for your balance sheet.

Why steel siding makes sense for commercial projects in Salt Lake City

Our climate swings hard. We get harsh UV, lake‑effect snow, spring wind, and freeze‑thaw cycles that make lesser materials crack or peel. Commercial steel siding handles that cocktail without blinking. High‑grade steel with Galvalume or galvanized coatings resists rust. Factory finishes like Kynar 500 keep color true under high-altitude sun. Expansion and contraction? Handled, with the right profiles and details.

It’s not only about weather. Steel is naturally noncombustible—an edge for risk management in dense urban zones or light-industrial districts. It laughs at pests. It shrugs off errant shopping carts. Many graffiti-resistant finishes mean tags wipe away with the right cleaner and a little patience.

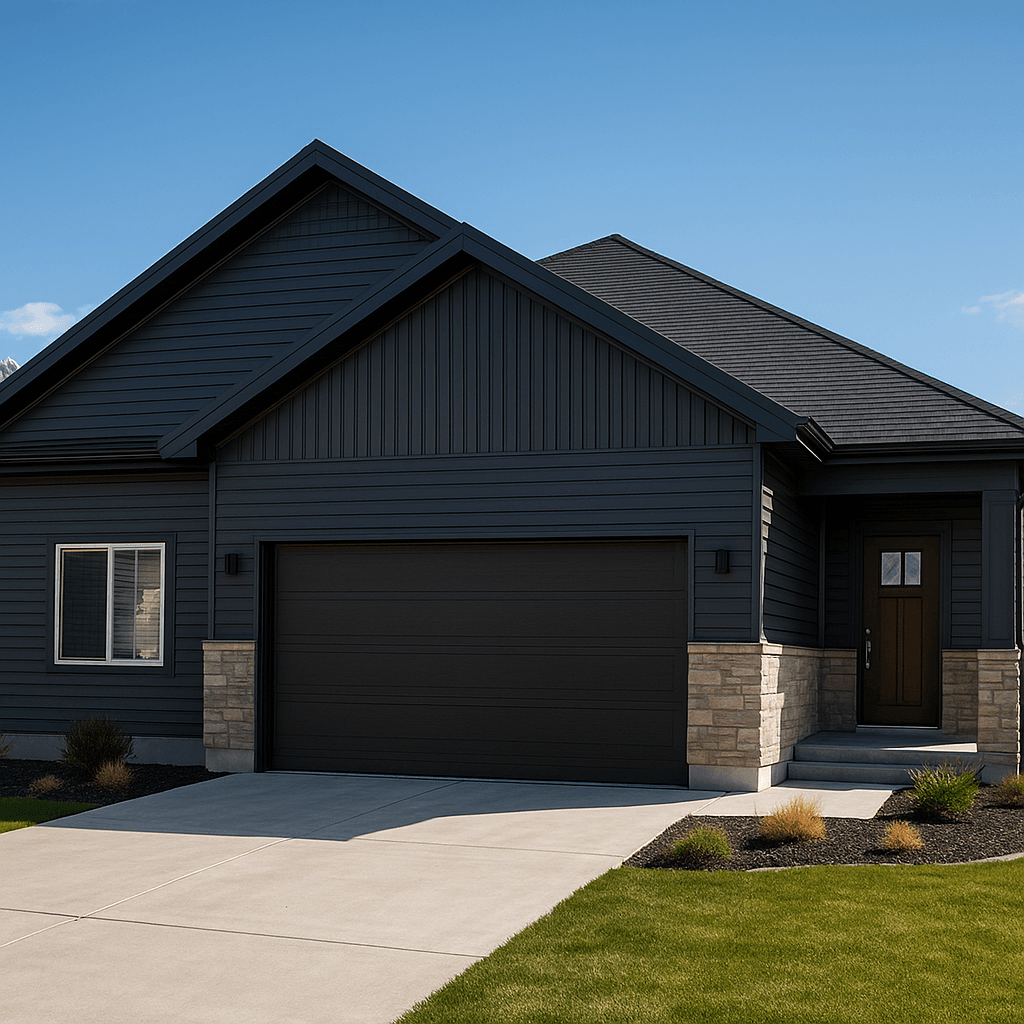

And you know what? It looks sharp. Today’s steel siding comes in plank, board‑and‑batten, and crisp architectural panels with concealed fasteners. That “warehouse only” look is old news. You can brand your façade with color, texture, and lines that stop traffic on 300 South or along State Street.

The cost story: sticker price vs. cost of ownership

Let me explain. A lot of folks compare bids and pick the cheapest number. But buildings don’t live on the day of the bid; they live for decades. Steel siding often carries a higher initial cost than basic vinyl, but it pays you back in lower upkeep, fewer repaints, and less downtime.

| Material | What it handles well | Typical lifespan in SLC |

|---|---|---|

| Steel siding (PVDF finish) | UV, snow, wind, fire, impact, pests | 40–50+ years with simple care |

| Fiber cement | Fire, impact; needs repainting | 25–35 years; paint 10–15 years |

| Stucco (EIFS) | Design flexibility; must control moisture | 20–30 years; repairs vary |

Lower maintenance means fewer service calls and fewer “Sorry, we’re closed for repairs” signs. Some insurers even offer favorable rates when buildings use fire-resistant siding and noncombustible exteriors; worth a call to your broker.

There’s also tax treatment. Many commercial improvements can be depreciated, and energy upgrades may qualify for incentives. We’re not your CPA, but we have seen steel projects play well with smart financing.

It doesn’t have to look industrial: styles that sell your brand

Modern steel systems are chameleons. Want clean lines for a tech office in the Granary District? Go with flat or ribbed architectural panels and a muted charcoal. Have a customer-facing retail strip near Sugar House? Consider steel lap siding with a wood‑tone finish that still wears like metal. Restaurant with a mountain vibe? Board‑and‑batten steel makes a strong statement without the maintenance of actual wood.

We install panels with concealed fasteners for a smooth, high‑end finish, or exposed fasteners where a rugged aesthetic fits. Most come in rich, UV‑stable colors built on Kynar 500 resins; that means fade resistance that’s more than marketing fluff. Need your brand colors? Let’s talk custom coils and factory lead times.

Energy performance and staying code‑smart

Salt Lake City follows IECC energy codes, and many commercial buildings need continuous insulation outside the framing. Steel plays nice with that. We design rainscreen assemblies that let the wall dry, add continuous insulation to cut thermal bridging, and integrate air and water barriers so the envelope performs as a system. It’s not flashy, but it’s how you get predictable energy bills and fewer moisture problems.

There are “cool” finish options that reflect more solar heat, helping with cooling loads on south and west exposures. Recycled content is another quiet win—steel is one of the most recycled materials on earth. If your project is chasing LEED or a green checklist, commercial steel siding can contribute.

Safety, fire, and risk management

Noncombustible cladding matters near property lines, in mixed‑use zones, or anywhere you want to lower risk. Steel won’t burn, and it doesn’t add fuel to a fire. It also resists embers and radiant heat. For impact, thicker gauges hold up to wind‑blown debris and hail common along the valley floor during spring storms.

Lightning? The siding isn’t a magnet. As with any building, a proper grounding system manages strikes. Seismic? Lightweight cladding reduces mass on the wall, which engineers like in an earthquake zone. It’s the little things that add up to peace of mind.

Maintenance made boring, in the best way

Maintenance for low maintenance siding should be simple. With steel, it is. Rinse it once or twice a year. Brush away de-icing residue near grade. Touch up any deep scratches to protect the coating. That’s basically it.

Fresh graffiti? Many PVDF coatings accept graffiti removers that won’t haze the finish. Bird droppings or tree sap along the Jordan River Parkway? Warm water, mild soap, soft brush—done.

Installation timeline—and why winter doesn’t scare us

Unlike stucco or masonry, steel doesn’t need cure time or perfect humidity. We can work in winter, which helps busy crews and tight schedules. Panels arrive cut to size, and our team handles layout, flashing, and trim so water stays out and expansion happens where it should. Less waiting, fewer weather delays, faster closeouts. It’s not magic; it’s a system.

Common questions we hear

Will steel siding rust in our snowy winters?

Quality matters. We specify Galvalume or G90 galvanized substrates with factory-applied coatings. Follow the maintenance basics and avoid dissimilar-metal contact at details, and rust worries fade fast.

What about dents?

Thicker gauges resist most common impacts. If a forklift kisses the wall, we can swap a panel or plank without tearing apart the whole elevation.

Is steel noisy in wind?

Proper fastening, sheathing, and insulation kill vibration. Inside a finished space, you won’t notice the siding. If you do, something’s off—and we’ll make it right.

Can steel handle our UV and elevation?

That’s where Kynar 500 finishes shine. They hold color and gloss in high‑UV locations like Salt Lake City. Fading is minimal when you choose proven coatings.

Mini scenarios from the Wasatch Front

Retail suite on Highland Drive: Owner wanted a modern face without constant repainting. We used steel lap siding with a warm wood‑tone finish and crisp black trim. Energy bills dropped after we added continuous foam. Foot traffic went up; the storefront photographs beautifully.

Distribution warehouse in West Valley: Old fiber cement was spalling. We moved to ribbed steel panels with concealed fasteners on the public side and exposed fasteners on the back. Fast install, better wind resistance, and the brand went from tired to tidy in a week and a half.

Mixed‑use near 900 South: Board‑and‑batten steel for the street level; flat panels above. Fire resistance satisfied the plan reviewer. The finish ties in with the neighborhood palette without more maintenance for the property manager.

How Utah Siding & Exteriors makes it easy

We’re local. We know what our weather does to buildings from downtown to Millcreek. Our team handles design‑assist, product sourcing, and installation for steel siding in Salt Lake City that meets code and looks the part.

We work with trusted brands and systems—EDCO steel siding profiles for a wood‑like look, architectural panels from respected manufacturers like Metal Sales, MBCI, and PAC‑CLAD for modern lines, and trim packages that finish clean. We coordinate with your GC, architect, or facilities lead. No drama, just clear schedules and tidy job sites.

What can go wrong—and how we prevent it

Honesty time. Metal can “oil‑can,” which is a subtle waviness. It’s cosmetic, but we still aim to avoid it. We choose the right gauge, add stiffening beads when needed, and manage fastener spacing. Expansion gaps and slotted holes let panels move without stress. We isolate dissimilar metals to prevent galvanic corrosion. Flashing and end dams keep water out of places it doesn’t belong.

These are the details that don’t make Instagram, but they make buildings last. That’s our lane.

If you’re weighing the decision, here’s a quick checklist

- Life‑cycle cost Are you measuring maintenance, repainting, and downtime over 20+ years?

- Brand and curb appeal Will the façade help leasing and sales, not just survive winter?

- Risk profile Fire resistance, impact resistance, and code compliance off your worry list?

- Energy and comfort Can you add a rainscreen and continuous insulation without re‑engineering the entire wall?

- Schedule Do you need a winter‑friendly install to hit your opening date?

If you answered “yes” to most of these, commercial steel siding is likely the smart move.

Ready to talk steel siding? Let’s get you a solid plan

Whether it’s a tidy façade refresh or a full envelope upgrade, Utah Siding & Exteriors can help you compare options, pick profiles, and lock a schedule that works for your business. We’ll walk the site, talk through colors and finishes, and give you a clear, line‑by‑line proposal—no guesswork.

Call 801-509-9241 to reach our team, or hit Request a Free Quote and we’ll respond fast. If you want a second opinion on a plan you already have, that’s fine too. We’re happy to be the straight‑talkers in your corner.