Fiber Cement Siding didn’t start out as the chic, durable option that architects and neighbors now drool over. It began as a pragmatic answer to a pair of problems: make cladding that resists fire and rot, and do it without the maintenance headaches of wood. Fast-forward a few decades, and what was once purely functional has become design-forward, performance-rich, and surprisingly versatile. If you live in Salt Lake City or manage a property here, knowing how this material evolved can help you make smarter choices for your home or business — and, yes, it matters more than you might think when winter and spring storms roll through the valley.

How it all started — humble genius

The story begins back when builders were fed up with wood’s quirks. Shrinkage, rot, termites — the list goes on. Around the mid-20th century, manufacturers began experimenting with cement mixed with cellulose fibers. You know what? That simple combo solved a lot of headaches. It resisted fire better than wood and didn’t swell or rot the way wood did. Early panels were heavy and boring-looking, but they worked. That was the point: durability first, looks later.

Let me explain. Early fiber cement was more of a survivalist solution — think work boots rather than designer sneakers. It offered a level of protection that wood couldn’t, especially in areas prone to moisture and pests. But designers were quick to notice potential. Soon, textures and finishes arrived that made fiber cement more appealing to homeowners and architects alike.

What it’s made of — simple chemistry, big gains

In plain terms, fiber cement siding mixes cement, sand, and cellulose fibers. The fibers add tensile strength; the cement and sand give density and resistance. That’s the recipe, though manufacturers add their own tweaks — binders, color pigments, and surface treatments — to improve paint adhesion or to mimic wood grain.

Here’s the practical takeaway: it’s dense but not unmanageable. That sounds a little contradictory — dense yet workable — but modern manufacturing (pressing, autoclaving, extrusion) makes large but manageable panels possible. James Hardie, Nichiha and other brands refined production so pieces are straight, predictable, and more forgiving in the field. For installers, that predictability saves time. For you, that means tighter seams and fewer callbacks.

Modern performance — tough as nails, but polite about it

Honestly, one of the biggest reasons people choose fiber cement is performance. It checks a lot of boxes:

- Fire resistance: It won’t feed a flame like wood can, which is reassuring in areas with wildfire concerns.

- Moisture resistance: It stands up to rain and snow better than traditional Wood Siding.

- Longevity: Expect decades of service when it’s properly installed and painted.

- Low maintenance: It doesn’t need yearly treatments — a wash and periodic repainting are usually enough.

But here’s a nuance: it’s durable, yes, yet it still needs a thoughtful installation. Poor flashing or sloppy caulking defeats much of its advantage. So the product itself is strong; the system — install details, trim, and paint — must be solid too. That’s where an experienced contractor comes in; they make the good product great.

Design trends — from boxy to breathtaking

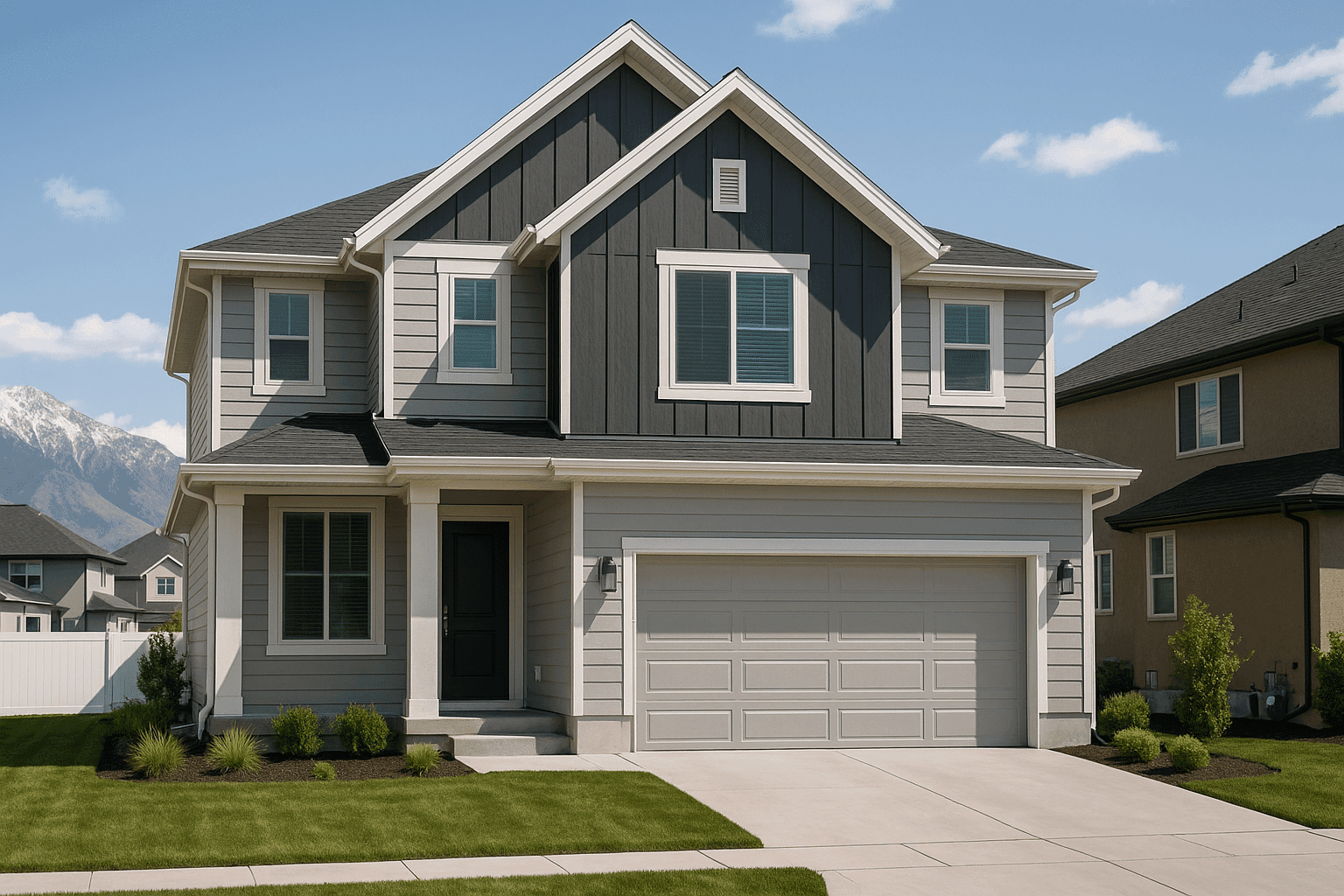

At first, fiber cement looked utilitarian. Now? It’s everywhere — Cape Cod clapboard, crisp board-and-batten, bold modern panels. The industry learned that people wanted durability and beauty. So finishes evolved: deep wood grains, smooth finishes, and contemporary large-format panels that mimic stone or stucco. The range is wide enough that you can pick something traditional for a Tudor revival or something edgy for a new mixed-use building in downtown Salt Lake City.

You might wonder: does it really look like wood? Often yes — very convincingly. And sometimes it’s better than wood because it won’t crack or cup in our freeze-thaw cycles. That’s a bit of a contradiction: it looks warm and natural but behaves like an engineered product. Let that sink in for a moment.

How it behaves in Salt Lake City’s climate — spoiler: it handles it well

Salt Lake City poses a unique combo of weather: dry summers, snowy winters, and spring runoff. Fiber cement plays nicely here for several reasons. It tolerates temperature swings better than many materials, and it resists moisture-driven rot that can creep into wood after a wet spring.

Wildfire risk — a real concern in parts of Utah — also favors fire-resistant siding, especially for homes near foothills. And UV? Some modern fiber cement products include UV-stable paints and coatings that keep color life strong under the bright Wasatch sunlight. Still, finish quality matters: cheaper field-applied paints will fade sooner than factory-applied baked-on finishes.

Installation and maintenance — not glamorous, but vital

Installation separates the winners from the also-rans. Here’s the thing: fiber cement is forgiving, but not magical. It needs proper flashing, insect barriers, and careful trim work. You’ll want a pro who knows how to seal window and door transitions and detail eaves so water doesn’t sneak behind the cladding.

Maintenance is pleasantly low-effort. A periodic hose-down, check caulks, and repaint every 10–15 years (depending on finish) will keep it looking sharp. If a board gets damaged, it’s replaceable; spot repairs are straightforward, but matching the paint color years down the road can be tricky. Keep records of the paint code — you’ll thank yourself later.

How it stacks up — quick look (table)

| Material | Durability | Appearance Options |

|---|---|---|

| Fiber cement | High — fire and moisture resistant | Wide — wood grain, smooth, panels |

| Vinyl | Moderate — can warp in heat | Good — limited textures, many colors |

| Wood | Variable — beautiful but needs upkeep | Excellent — authentic grain and character |

Who it’s for — homeowners and businesses alike

If you’re a homeowner in Salt Lake City who wants a long-lasting finish, fiber cement is attractive. It gives you style without the constant sanding and staining wood demands. For business owners, the appeal is similar — long life, minimal downtime for maintenance, and a professional look that lasts through Utah seasons.

Consider these quick points before you decide:

- Budget: Initial cost is often higher than vinyl, but lifespan and lower maintenance can offset that.

- Design goals: If you want a custom look, fiber cement offers more authentic textures than most alternatives.

- Resale: Homes with durable, low-maintenance exteriors often keep buyer interest high — which matters in a competitive market.

What’s next — trends to watch

The material keeps getting better. Manufacturers are improving paint longevity, making larger-format panels, and refining installation systems that reduce labor time. There’s also a trend toward mixing materials — fiber cement with metal accents, with stone veneers, or with engineered wood — to create facades that are both modern and welcoming.

You might hear about greener options too: lower-energy manufacturing and recycled content. That’s happening slowly, but progress is real. And yes, smart coatings that resist dirt and algae? They’re getting better, which means less washing for you — a small win with a big payoff over years.

Wrapping up — should you choose fiber cement?

Short answer: for many homes and businesses in Salt Lake City, it makes a lot of sense. It balances looks and performance in a way few other siding materials do. It’s not flawless — installation quality matters, and the upfront price can be higher — but when you factor in longevity, fire resistance, and low upkeep, it often becomes the smarter long-term choice.

If you’re wondering where to start, here’s an easy next step: talk to a local pro who knows both the product and our climate. You want someone who will detail windows, roofs, and trim so the system performs, not just a surface install.

Utah Siding & Exteriors specializes in helping Salt Lake City homeowners and businesses pick the right siding and get it installed the right way. Curious? Give us a call at 801-509-9241 or click to Request a Free Quote. We’ll walk you through materials, costs, and timelines — honestly, no pressure. Let’s get your exterior ready for whatever Utah throws at it.